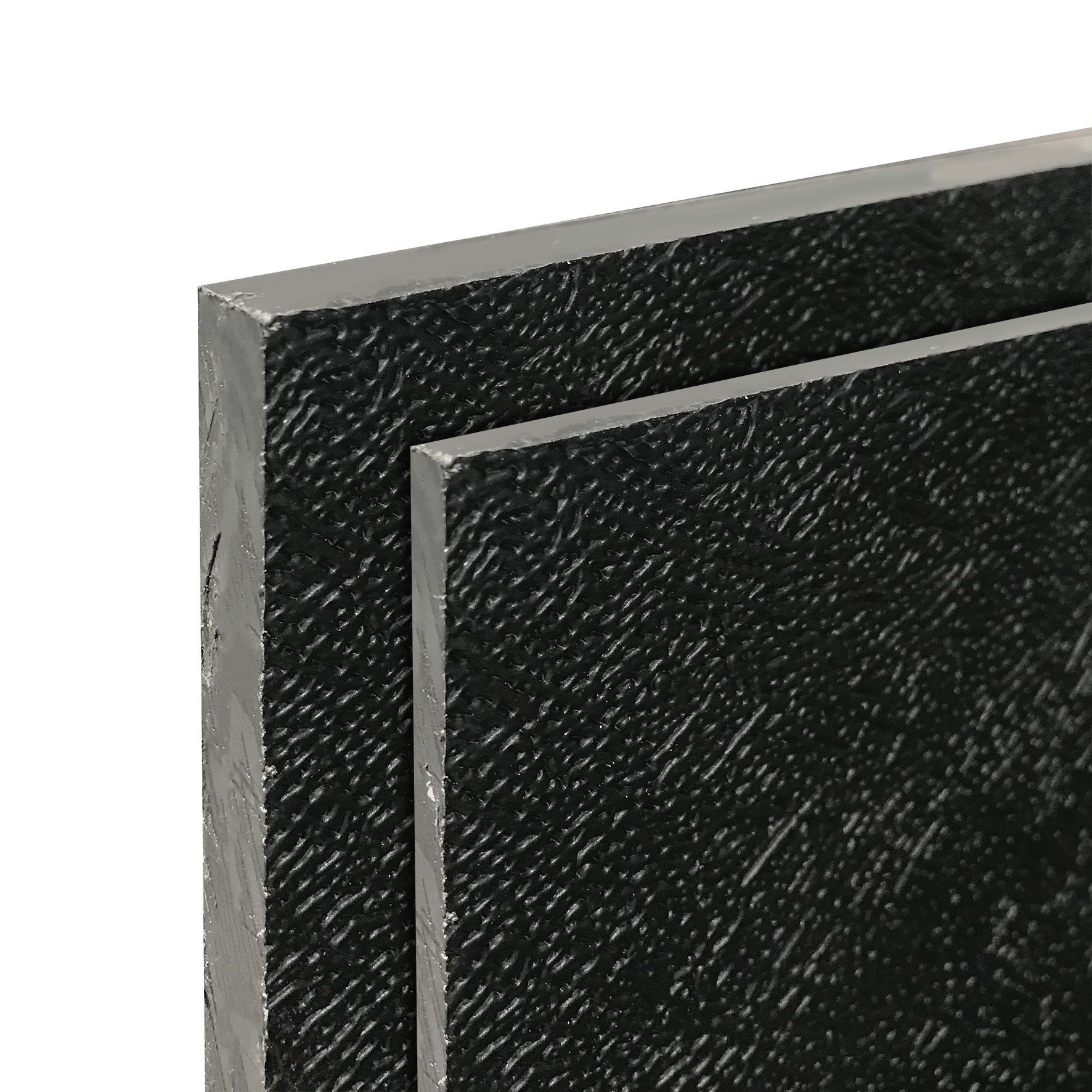

Polypropylene sheet with an embossed pattern, the embossing gives a textured surface, which may be preferable to smooth polypropylene in some applications. Generally, easy and quick to install and will withstand repeated steam cleaning. Polypropylene resists attack from most chemicals, including alkali detergents and is corrosion resistant. It is non-toxic and many grades are approved for use in contact with foodstuffs. Although PP is the hardest and stiffest polyolefine it suffers from high creep, poor UV resistance and rapid oxidisation in contact with copper.

There are two basic types;

Homopolymer - High impact strength and is both rigid and resilient and is tough at room temperatures. It tends to become brittle below about -10°C. Working temperature is 0 to 100°C

Copolymer - Very "tough" but mechanical properties and upper service temperature is about 10% less than Homopolymer.

Working temperature: -40°C to 90°C

General Applications for Polypropylene

Almost any kind of food industry application from abattoirs and fish processing plants to dairies, bakeries and commercial premises, to kitchens and general food preparation areas.