Clear Polycarbonate sheet is a rigid transparent plastic material that exhibits extremely high impact strength, appoximately 250 times that of glass, over a wide temperature range. It is weather resistant, some grades are UV resistant and it possesses good fire properties. It is also a good thermal and electrical insulator. It is this almost unique combination of impact strength, transparency and maintenance of physical properties over a large temperature range that makes it so useful to the architect and designer.

Surfaces are 'soft' and can be easily scratched. There is limited resistance to organic solvents. Polycarbonate tends to be notch sensitive, meaning a drill hole or edge chip for example will reduce its impact resistance in that area. It is easy to cut, machine and shape and can be cold bent to a radius of 150 x thickness without any ill effect.

General Applications for Clear Polycarbonate

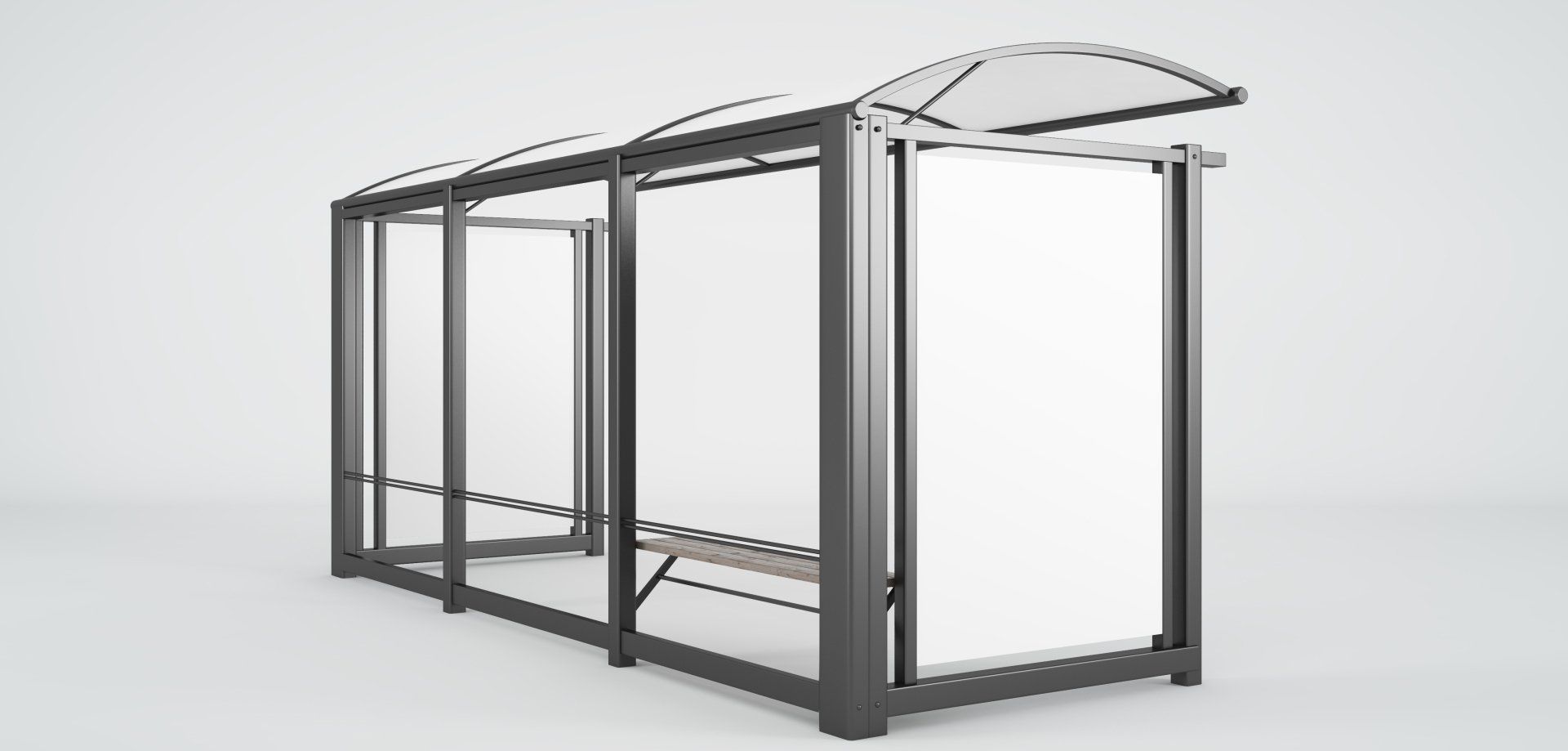

Its main use is as anti vandal glazing, safety and security screen. Ideal for bus shelter glazing, sports halls, schools and public areas. It is frequently used as architectural barrel vaulted roofing. It is often used for machine guards and enclosures, visors and police rioy shields, street furniture and lighting.